HOME

CONTACT

REFERENCES

SERVICES

ABOUT US

TBFrömmer

Consultancy for Water and Land Management and Engineering

RECENT PROJECTS

| Date | 09/2018 – 12/2019, intermittent input | |

| Location | Kosovo | |

| Employer | Posch & Partners Consulting Engineers, Austria | |

| Position | Waste water treatment expert | |

| Description | Update of the old Feasibility Studies for the improvement of the sanitation systems and construction of wastewater treatment plants in the towns Mitrovica, Gjilan and Vushtrii, range of capacity of the evaluatedWWTPs 45.340 to 149.504 p,e.60 | |

| Date | 03/2018 – 05/2018 | |

| Location | Nepal | |

| Employer | Landell Mills Ltd | |

| Position | Wastewater Treatment / SBR expert | |

| Description | Bagmati River Basin Improvement Project | |

| feasibility study for the construction of a WWTP at the conjunction of the Tukucha Khola snd the Bagmati River, integration of the WWTP into the historic (national heritage) and cultural important area | ||

| sewage volume Q = 17,300 m³/d. connection load BOD5 = 8,650 kg/d | ||

| Preliminary design of a WWTP operating according to the SBR principle; comparison and evaluation of several variants of WWTP, cost assessment | ||

| Date | 11/2017 – 05/2018, intermittent input | |

| Location | Azraq /Jordan | |

| Employer | GITEC IGIP GmbH | |

| Position | Waste Water Treatment Expert | |

| Description | The WWTP that is situated in the Refugee Camp. It receives the faecal sludge that is collected in the storage pits of the refugee camp with about 33,000 residents. The plant comprises screening, an inflow equalisation tank, 3 lines pre-treatment container and 3 lines for biological purification each with 2 streets MBBR container, secondary clarification, chlorination for disinfection and 2 sludge storage tanks. The biological purification did not match the purification goals any more. On the basis of detailed investigation of the current operation and loading situation a plan was developed to improve the purification efficiency through modification of the operation routine and installation of new equipment. | |

| Date | 11/2017 – 02/2018 | |

| Location | Palestine | |

| Employer | DORSCH International Consultants GmbH | |

| Position | Project Manager for the Inception Phase | |

| Description | Establishment of a Sanitation Master Plan for the service area of Jerusalem Water Undertaking (JWU) in the the Governorates Ramallah – Al Bireh and Jerusalem | |

| Date | 11/2017 | |

| Location | Sousse / Tunisia | |

| Employer | Ipp Consult | |

| Position | Waste Water Treatment Expert | |

| Description | Preparation of the tender documents for the implementation of the tertiary treatment (sand filtration, UV disinfection) at the WWTP Sousse Hamdoun, specification of the mechanical and piloting equipment | |

| Date | 07.11.2017 | |

| Location | Cakovec / Croatia | |

| Employer | Edtmayer d.o.o., Croatia | |

| Position | Process Engineer | |

| Description | Assistance for the start-up of the WWTP WWTP Novo Selo | |

| hydraulic load Q = 750 m³/d; qmax = 72 m³/h | ||

| pollution load .BOD5 = 300 kg = 5,000 p.e. | ||

| The works accomplished included | ||

| · Definition of the operation parameters | ||

| · Preparation of the operation manual | ||

| · Instruction of the operators | ||

| Date | 12/2016 – 06/2017 | |

| Location | Albania | |

| Employer | Posch & Partners Consulting Engineers, Austria | |

| Position | Waste water treatment expert | |

| Description | Consulting Services for the Project “Municipal Urban Infrastructure III – Berat, Kucova and Librazhd (Albania)" | |

| Elaboration of a Feasibility Study for the improvement of the water infrastructure of the towns Berat and Kucova (update of the feasibility study elaborated in 2011). The two towns are situated in the service area of the Water utility company UK Berat-Kucova. A list of measures to improve the water supply infrastructure and collection of waste water of the two municipalities and surrounding villages has been prepared.A major importance was laid in the assessment of the population development, water demand and sewage production. The pollution load for the design of individual WWTPs was assessed. | ||

| A corresponding feasibility study and a list of measures for the villages Librazhd and Prrenjas were prepared. The two towns are serviced by the Water Utility company UK Librazhd | ||

| Date | 03/2016 – 06/2016 | |

| Location | Austria / Kazakhstan | |

| Employer | hydrophil GmbH | |

| Position | Waste water treatment expert | |

| Description | The WWTP of Astana has a capacity of 950,000 p.e.60 (year 2018) and will be upgraded to to a load of 1,220,000 p.e. for the year 2030. In the study the production of excess sludge until 2030 was assessed and different options for the manipulation of excess sludge (digestion, energy production, dewatering, drying, drying beds, dumping at a landfill, use in agriculture, incineration, pyrolysis) were evaluated. The main sludge treatment plants were designed on a conceptual basis | |

| Date | 09/2015 – 03/2016 | |

| Location | Palestine | |

| Employer | GITEC Consult GmbH | |

| Position | Team Leader | |

| Description | “Consulting Services for the preparation of the detailed Design and Tender Documents, Assistance of the PEA in Tendering and Contracting and Construction Supervision”for the Construction of the WWTP Salfeet. | |

| Aconceptional design of several process technologies and evaluation of the process and construction and operation costs was prepared for the final decision on the purification process. | ||

| The Detail engineering of the selected technology (Imhoff tank and trickling filter) was executed and the tender documents for the construction of the selected plant (Yellow FIDIC) were prepared. | ||

| The WWTP has been designed for a capacity of 20,500 p.e.60 for the design horizon 2032 and 28,000 p.e.60 for 2045 | ||

| Date | 11/2014 – 08/2015 | |

| Location | Durres / Albania | |

| Employer | GfA Consulting Group GmbH | |

| Position | Process Engineer | |

| Description | Technical Assistance to the Water Supply and Sanitation Sector Albania": | |

| Strengthen water utilities and LGUs. The main objective of the component was to increase the managerial and operational capacity of the utilities, and to establish a framework for training provision in the sector. | ||

| · Provided technical assistance for the operation of the WWTPs at Durres (activated sludge with digestion and bio-gas works power generation), Kavaje (trickling filters), and Vlore (facultative lagoons) in order train the staff of WWTPs on site for the general operation of a WWTP and sludge digestion | ||

| · Preparation and guidingof a study tour for technical and administrative staff of the GDWSS to Austria, paying site visits to several operating WWTPs, explanation of the applied process technologies, discussion with the operators learning about the daily duties and works and administrative tasks | ||

| · Provision of 5 days training through a 15 days workshop (including lectures) in Tirana, Albania, to key GDWSS staff in the selection of treatment processes to meet identified needs | ||

| · Expansion of the capability of the existing benchmarking system to accept wastewater performance indicators (sewerage, wastewater treatment, and effluent quality). | ||

| Date | 06.12.2014 | |

| Location | Lao Cai / Vietnam | |

| Employer | Witteveeen Bos | |

| Position | Process Engineer | |

| Description | Elaboration of the project of the construction of a waste water treatment plant for the treatment of the domestic sewage. Process calculation, design of the WWTP with primary clarification, trickling filters pre denitrification, phosphorus removal by precipitation and disinfection. Construction in 2 stages | |

| Project status: preparation of the tendering process | ||

| Stage 1 | ||

| hydraulic load Q = 4,300 m³/d; qmax = 282 m³/h | ||

| pollution load .BOD5 = 612 kg = 10,212 p.e. | ||

| Stage 2 | ||

| hydraulic load Q = 9,750 m³/d; qmax = 640 m³/h | ||

| pollution load .BOD5 = 1,390 kg = 23,160 p.e. | ||

| The works accomplished included | ||

| · Process Calculation, detailed engineering of all units of the WWTP | ||

| · Specification of the constructions and equipment | ||

| · Hydraulic calculations | ||

| · Process Description | ||

| Date | 05.11.2014 | |

| Location | Gutenstein / Austria | |

| Employer | Edtmayer Systemtechnik GmbH, Austria | |

| Position | Process Engineer | |

| Description | Elaboration of the project of the construction of a waste water treatment plant for the treatment of the sewage from a soft drinks producing factory and the domestic sewage produced by the employees and workers. Process calculation, design of the WWTP operating according to the continuous flow process with floating biofilm carrying substrates, specification of the equipment. Project status: application for the permission for the construction of the plant and discharge of the purified water to a river | |

| hydraulic load Q = 45 m³/d; qmax = 5 m³/h | ||

| pollution load .BOD5 = 65 kg = 1,083 p.e. | ||

| The works accomplished included | ||

| · Process Calculation, detailed engineering of all units of the WWTP | ||

| · Specification of the constructions and equipment | ||

| · Hydraulic calculations | ||

| Process Description | ||

| Date | 07.08.2014 | |

| Location | Cakovec / Croatia | |

| Employer | Edtmayer d.o.o., Croatia | |

| Position | Process Engineer | |

| Description | Process calculation, design of the WWTP operating according to the SBR process, specification of the equipment for the tendering of the construction of the WWTP Novo Selo | |

| hydraulic load Q= 750 m³/d; qmax = 72 m³/h | ||

| pollution load .BOD5 = 300 kg = 5,000 p.e. | ||

| The works accomplished included | ||

| · Process Calculation, detailed engineering of all units of the WWTP | ||

| · Specification of the constructions and equipment | ||

| · Hydraulic calculations | ||

| · Process Description | ||

| Date | 12/2012 – 26.11.2013 | |

| Location | Ivano Frankivsk / Ukraine | |

| Employer | Posch & Partners Consulting Engineers, Austria | |

| Position | Team Leader, Process Engineer | |

| Description | Supervision of the rehabilitation of the waste water treatment plant of Ivano Frankivsk. Process Engineer, Control of the Design of the WWTP for upgrading of the capacity of the plant to 250,000 P.E with nitrogen and phosphorus removal | |

| Date | 06/2012 – 12/2013, 04/2016 until mid 01/2017 intermittent input | |

| Location | Drnis / Croatia | |

| Employer | Posch & Partners Consulting Engineers | |

| Position | Team Leader | |

| Description | Supervision of the construction works of the WWTP of the town Drnis. | |

| The capacity of the plant arises to 4,000 P.E with nitrogen and phosphorus removal, excess sludge stabilisation | ||

| Date | 08/2013 – 09/2013 | |

| Location | Romania / Austria | |

| Employer | WTE Branch Austria | |

| Position | Waste water treatment expert | |

| Description | Design of WWTPs for the elaboration of offers for the construction of WWTPs “in the tendering procedure. Load: | |

| WWTP Vaslui: | ||

| hydraulic load Qaver= 18,857to Qmax = 24,180m³/d | ||

| pollution load .BOD5 = 5,137 kg = 85,623 p.e. | ||

| WWTP Barlad: | ||

| hydraulic load Qaver= 20,481 to Qmax = 24,506m³/d | ||

| pollution load .BOD5 = 4,662 kg = 77,698 p.e. | ||

| The works accomplished included | ||

| · Process Calculation, detailed engineering of all units of the WWTP | ||

| · Specification of the constructions and equipment | ||

| · Hydraulic calculations | ||

| · Process Description | ||

| Date | 06/2012 – 04/2013 | |

| Location | Drnis / Croatia | |

| Employer | Posch & Partners Consulting Engineers | |

| Position | Team Leader | |

| Description | Supervision of the Construction of Water Supply and Sewerage System in Drniš | |

| The realized works included: | ||

| Water supply: L = 4,873 m (rehabilitation + new lines) | ||

| Sewerage rehabilitation : L = 1,757 m | ||

| New sewerage pipelines L = 5,788 m | ||

| Date | 11/2012 –05/2013 | |

| Location | Montenegro / Austria | |

| Employer | WTE Branch Austria | |

| Position | Waste water treatment expert, SBR expert | |

| Description | WWTP “Kotor Tivat” in Montenegro. Load: | |

| stage 1 summer / winter season: 8.047 m³/d / 13.623m³/d P.E. 34.500 / 72.500 | ||

| stage 2 summer / winter season: 9.042 m³/d / 16.514m³/d P.E. 39-000 / 90.000 | ||

| The works accomplished included | ||

| · Process Calculation, detailed engineering of all units of the WWTP operating according to the SBR principle taking into consideration the huge variation of the connection load in the summer respectively winter season and the construction of the WWTP in 2 stages | ||

| · Specification of the constructions and equipment | ||

| · Hydraulic calculations | ||

| · Process Description | ||

| Date | 06 + 09 /2013 | |

| Location | Palestine West Bank (Nablus West) | |

| Employer | GITEC Consult GmbH | |

| Position | Team Leader | |

| Description | Feasibility Study for the connection of industrial entities to the public sewerage system and treatment of industrial waste water in the WWTP Nablus West: | |

| the improvement of the sanitation system in the catchment area Nablus West has been realised to a large extent. The WWTP Nablus West has officially been put into operation. Industries being connected or not connected to the sewerage have however not been obliged to install treatment facilities for the sewage before discharge. Therefore the effluent of the factories represents a hazard for the operation of the WWTP and quality of the produced excess sludge. | ||

| On the basis of a recent survey executed by Nablus Municipality of industrial factories that are situated inside and outside the boundaries of Nablus Municipality that may sooner or later discharge sewage directly or indirectly to the trunk line the Consultant evaluated the possibilities of discharge and prepared a strategy how to include the factories into an environmentally sound sanitation concept. Several process technologies have been compared and the applicability been evaluated | ||

| Date | 02/2012 – 09/2012 | |

| Location | Palestine West Bank (Nablus East) | |

| Employer | GITEC Consult GmbH | |

| Position | Team Leader | |

| Description | Sewerage Nablus East, Palestine. Consultancy Services For The Elaboration of a Feasibility Study | |

| The western catchment area of the town is connected to a sewerage system and treatment plant. The eastern part of the city of Nablus however still discharges to a nearby Wadi without any treatment. | ||

| A feasibility study for the construction of a WWTP in order to determine the best site and technology for the plant was elaborated. The determination of the site should respect options to establish a centralized system connecting surrounding villages to the WWTP or determine the necessity to establish a decentralized system using septic tanks or building small individual WWTPs. The study had to take into consideration social, economic and political aspects and to consider the possibilities of reuse of the treated waste water and excess sludge. The reuse aspect had to evaluate the possibilities or dertermine the obligation to find othrer ways of sludge disposal like transport to a landfill. | ||

| The projected included the assessment of reuse possibilities for the treated waste water and excess sludge and an Environmental Impact Assessment of the projected measures. The options of the participation of the Private Sector PSP were discussed. | ||

| Date | 12/2007 – 08/2012 | |

| Location | Tunisia (Sousse Sud, Bizerte and 11 towns of the Medjerdah valley) | |

| Employer | Fichtner WT | |

| Position | Project Director / Team Leader | |

| Description | Technical Assistance for the improvement of the operation of the WWTP of Sousse Sud, Bizerte and 11 plants f the Medjerdah valley (4.000 to 157.000 p.e.60) | |

| These plants have been in operation already for a plenty of years (Sousse Sud) or only a couple of years (Gaafour). The project aimed at establishing an inventory(data collection, diagnosis of the situation)of the state of equipment, constructions and purification efficiency. On the basis of the knowledge of the current situation the possibilities of an improvement of the operation and purification efficiency was evaluated and a catalogue of measures has been established in order to improve the treatment quality and energy efficiency of all WWTPs of the project. Respecting the financial capacity of the country and skills of the staff measures have been applied and the their impact on the efficiency have been verified | ||

| Date | 08/2008 – 05 / 2010 | |

| Location | Ben Guérir, Rabat / Morocco | |

| Employer | Fichtner WT | |

| Position | Waste water treatment expert | |

| Description | Design of the water treatment plant of the city Ben Guérir. The purification demand has been determined by the demand of the financing company (OCP) to reuse the purified water for industrial processes (mining of phosphorus). The plant also provides biogas production by anaerobic digestion of the excess sludge and energy production | |

| stage 1(2020) P.E60. 55.880 | ||

| stage 2 (2040) P.E.60 111.130 | ||

| The works included: | ||

| · Preliminary design | ||

| · Detail design | ||

| · Elaboration of the tender documents | ||

| · Preparation of the technical documentation. | ||

| · Evaluation of the submitted offers | ||

| · Preparation of the proposal of awarding of the project | ||

| Date | 05/ 2007 – 08/09 | |

| Location | Neumarkt (Upper Austria, Austria) | |

| Employer | Jung Water Innovation GmbH | |

| Position | Waste water treatment expert | |

| Description | The existing plant of the community Neumarkt had to be upgraded from 2.000 to 3.500 p.e.60 in order to increase the capacity of the plant and achieve high purification efficiency. The design project for the upgrading (bassins, equipement, piloting routine) has been elaborated and the tendering documents been prepared | |

| Date | 06/ 2008 – 03/2009 | |

| Location | Khouribga, Rabat (Morocco) | |

| Employer | Fichtner WT | |

| Position | Waste water treatment expert | |

| Description | Technical Assistance for evaluation of the submitted technical offers and of the construction works and installation of technical and piloting equipement of the WWTP (115.000 p.e.60). | |

| In the tendering process a company has been awarded the contract to build that plant. All the documents and specifications elaborated by the company had to been checked and supervised | ||

| Date | 06 – 09 / 2008 | |

| Location | Songyuan / China | |

| Employer | Fichtner WT | |

| Position | Waste water treatment expert | |

| Description | Songyuan 290,000 inhabitants in the year 2010, estimated 314,000 in the year 2020 | |

| phase 1 Q = 50,000 m³/d | ||

| phase 2 Q = 100,000 m³/d | ||

| · Assistance to the Project Executing Agency (Songyuan: Water Discharge Company of Songyuan City) in completing the project preparation prior to an appraisal by KfW. | ||

| · Assessment of the adequate treatment capacity for o first implementation stage of the WWTP based on the analysis of water consumption patterns and definition of realistic forecast as well as analysis of the connection rate to the sewer network; | ||

| · Assessment of possibilities for a future extension of the WWTP; | ||

| · Assessment of the appropriateness of the proposed main sewer lines with regard to the connection of existing tertiary networks; | ||

| · Critical analysis of the proposed treatment objectives and assessment of the needs for tertiary treatment and potentialities of wastewater reuse; | ||

| · Critical assessment of the proposed wastewater and sludge treatment processes; | ||

| · Verification of cost estimate | ||

| Date | 06 – 09 / 2008 | |

| Location | Tonghua / China | |

| Employer | Fichtner WT | |

| Position | Waste water treatment expert | |

| Description | Tonghua 370,000 inhabitants in 2010 respectively 550,000 in 2020. | |

| phase 1 Q = 50,000 m³/d for biological treatment; storm water Q = 100,000 m³/d | ||

| phase 2 Q = 100,000 m³/d for biological treatment; storm water Q = 200,000 m³/d | ||

| Assistance to the Project Executing Agency (Tonghua Jieyuan Wastewater Treatment Company) in completing the project preparation prior to an appraisal by KfW. | ||

| · Assessment of the adequate treatment capacity for o first implementation stage of the WWTP based on the analysis of water consumption patterns and definition of realistic forecast as well as analysis of the connection rate to the sewer newtork; | ||

| · Assessment of possibilities for a future extension of the WWTP; | ||

| · Assessment of the appropriateness of the proposed main sewer lines with regard to the connection of existing tertiary networks; | ||

| · Critical analysis of the proposed treatment objectives and assessment of the needs for tertiary treatment and potentialities of wastewater reuse; | ||

| · Critical assessment of the proposed wastewater and sludge treatment processes; | ||

| · Verification of cost estimate | ||

| Date | 07 09/2008 | |

| Location | Mornag, Tunis (Tunisia) | |

| Employer | Fichtner WT, GFA Group | |

| Position | Waste water treatment expert | |

| Description | The decline of the ground water level already causes problems for the irrigation of agricultural areas. Therefore the administration and international donors try to find ways to reduce the impacts. One possibility is the reuse of treated waste water. In the project the possibilities of recharge of the ground water by the infiltration of treated sewage deriving from the WWTP Méliane II have been analised. The study also comprised the specification of a maybe necessary upgrading of the operating plant by the construction of a tertiary treatment including filtration and disinfection. | |

| The project has been elaborated by an interdisciplinary team of international engineers | ||

| Date | 03 – 04 / 2008 | |

| Location | Sulaibiya / Kuwait | |

| Employer | Fichtner, Utility Development Company W.L.L. | |

| Position | Waste water treatment expert | |

| Description | The WWTP had a daily capacity of up to 375,000 m³ and treated wastewater to potable quality for non-potable uses in the agriculture industry and aquifer recharge. The capacity of the plant should be increased to a daily capacity of up to 600,000 m³. The executed works included a review the existing operations as well as the new engineering and procurement arrangements for the plant expansion. | |

| · Detail engineering, process calculation of the activated sludge waste water treatment plant | ||

| · Hydraulic calculations | ||

| · Technical reports, process description, | ||

| · Estimation of the energy and consumables consumption in order to assess the annual operation costs | ||

| Date | 04 – 06 / 2007 | |

| Location | Suceava / Romania | |

| Employer | STRABAG AG | |

| Position | Waste water treatment expert | |

| Description | Design of the activated sludge waste water treatment plant with digesters for the production of biogas | |

| Pollution load) P.E60. 140.000 | ||

| · Detail engineering for the tendering of the construction of the WWTP including the sections of mechanical and biological treatment and sludge digestion and dewatering, process calculation of the activated sludge waste water treatment plant | ||

| · Hydraulic calculations | ||

| · Specification of the technical and piloting equipment (preparation of the technical documentation) | ||

| · Technical reports, process description, | ||

| · Estimation of the energy and consumables consumption in order to assess the annual operation costs | ||

| Date | 10.12.2005 | |

| Location | Dubai / United Arab Emirates | |

| Employer | Al Ahmadia Construction Company | |

| Position | Waste water treatment expert | |

| Description | Elaboration of a Feasibility Study for the construction of floating houses (the “Waterhomes” and “Floating homes”) with individual water supply, waste water discharge and energy supply at the Palm Jebel Ali project (ordered by the construction company Al Ahmadiah) | |

| Date | 05/ 2004 – 12 / 2005 | |

| Location | Hainburg / Austria | |

| Employer | Association of Villages around Hainburg | |

| Position | Project Manager, Process Engineer | |

| Description | · Pollution load P.E60. 15.000 | |

| · Preparation of the technical documentation for existing structures, buildings and equipment | ||

| · Feasibility study | ||

| · Preliminary design | ||

| · Process calculation, Detail engineering | ||

| · Elaboration of tender documents | ||

| · Evaluation of several offers (construction, technical equipment) | ||

| · Estimation of the energy and consumables consumption in order to assess the annual operation costs | ||

| · Supervision of the construction works (construction management) | ||

| · Supervision of the application of the plans of protection measures at work | ||

| Date | 11/2003 – 05/2004 | |

| Location | BEIJING XIAOHONGMEN - SLUDGE TREATMENT | |

| Employer | VA TECH Wabag | |

| Position | Waste Water Treatment Expert / Process Engineer | |

| Description | Q = 600,000 m³/d; peak= 780,000 m³/d | |

| Detail engineering of the sludge treatment line including: | ||

| static and mechanical sludge thickening, sludge digestion, digested sludge storage and dewatering; Biogas drying, sulphide removal, Biogas storage | ||

| Year: | 2003 | |

| Location: | Huludao (China), Vienna (Austria) | |

| Employer: | VA TECH Wabag | |

| Position | Waste Water Treatment Expert / Process Engineer | |

| Description | Detail design of the constructions of the WWTP operating according to the SBR principle, connection load 210,000 p.e. | |

| · Recalculation of the necessary volumes and dimensions of the constructions and optimising the layout of the plant (to match European standards) | ||

| · Calculation of the hydraulics of the plant, establishing of the piloting routine to match European standards | ||

| Year: | 2003 | |

| Location: | Nantong (China), Vienna (Austria) | |

| Employer: | VA TECH Wabag | |

| Position | Expert for biological sewage treatment systems and hydraulics of a sewage plant | |

| Description | Five oxidation ditch plant with pre denitrification an anerobic phosphorus removal, connection load 670.000 p.e. The plant operates with 5 oxidation basins connected in series with continuous flow without secondary clarifiers | |

| · Calculation of the hydraulics | ||

| · Setting up of the piloting routine of the plant | ||

| · Recalculation of the plant layout for the purification requirements of nitrification and denitrification | ||

| Year: | 2002 | |

| Location: | Pu Yang (China), Vienna (Austria) | |

| Employer: | VA TECH Wabag | |

| Position | Expert for biological sewage treatment systems and hydraulics of a sewage plant | |

| Description | Biological waste water treatment plant operating as a continuous flow plant. The connection load amounts to 270,000 p.e.60. | |

| · Calculation of the hydraulics of the plant | ||

| · Setting up of the piloting routine of the plant to match European purification standards | ||

| Year: | 2002 | |

| Location: | Shijiazhuang (China), Vienna (Austria) | |

| Employer: | VA TECH Wabag | |

| Position | Expert for biological sewage treatment systems and hydraulics of a sewage plant | |

| Description | Biological waste water treatment plant operating as a continuous flow plant. The connection load amounts to 250,000 p.e.60. | |

| Design of the Venturi flow meter for the effluent of the plant | ||

| Year: | 2001 | |

| Location: | Xining (China), Vienna (Austria) | |

| Employer: | VA TECH Wabag | |

| Position | Expert for biological sewage treatment systems and hydraulics of a sewage plant | |

| Description | Biological waste water treatment plant operating as a continuous flow plant. The connection load amounts to 300,000 p.e. | |

| Calculation of the hydraulics of the plant (300.000 p.e) | ||

| Year: | 2001 | |

| Location: | Shijiazhuang (China), Vienna (Austria) | |

| Employer: | VA TECH Wabag | |

| Position | Expert for biological sewage treatment systems and hydraulics of a sewage plant | |

| Description | Biological waste water treatment plant operating as a continuous flow plant. The connection load amounts to 250,000 p.e60. | |

| Establishing the piloting routine of the plant (250.000 p.e) | ||

| Year: | 2001 | |

| Location: | Xinji (China), Vienna (Austria) | |

| Employer: | VA TECH Wabag | |

| Position | Expert for biological sewage treatment systems and hydraulics of a sewage plant | |

| Description | Biological waste water treatment plant, orbal tank sytem, connection load 500.000 p.e. | |

| Calculation of the hydraulics of the plant (500.000 p.e). Setting up of the piloting routine of the plant (500.000 p.e) (orbal tank system) to achieve purification efficiency according to European Standards | ||

| Year: | 2000 - 2001 | |

| Location: | Kaifeng (China), Vienna (Austria) | |

| Employer: | VA TECH Wabag | |

| Position | Expert for biological sewage treatment systems | |

| Description | Biological waste water treatment plant operating as a Triple Oxidation Ditch system with continuous flow. The connection load amounts to 400.000 p.e. | |

| Setting up of the piloting routine of the plant to achieve purification efficiency according to European standards | ||

| Year: | 2000 | |

| Location: | Xuan Hua (China), Vienna (Austria) | |

| Employer: | VA TECH Wabag | |

| Position | Expert for design of waste water treatment plants according to the SBR principle | |

| Description | Biological waste water treatment plant with a connection load of 50,000 p.e., plant according to the SBR principle | |

| · Check of the design and layout of the plant (to match European standards) | ||

| · Establishing of the piloting routine of the plant as a Sequencing Batch Reactor to achieve purification efficiency according to European standards | ||

| Year: | 2000 | |

| Location: | Shijiazhuang (China), Vienna (Austria) | |

| Employer: | VA TECH Wabag | |

| Position | Expert for biological sewage treatment systems and hydraulics of a sewage plant | |

| Description | Biological waste water treatment plant, continuous flow plant, connection load 250,000 p.e.60 | |

| Calculation of the hydraulics of the plant | ||

| Year: | 2000 | |

| Location: | Shanqiu (China), Vienna (Austria) | |

| Employer: | VA TECH Wabag | |

| Position | Expert for biological sewage treatment systems and hydraulics of a sewage plant | |

| Description | Biological waste water treatment plant operating as a continuous flow plant. The connection load amounts to 80,000 p.e.60. | |

| Calculation of the hydraulics of the plant | ||

| Year: | 1998 | |

| Location: | Manila (Philippines); Vienna (Austria) | |

| Employer: | Puraqua Umweltanlagen GmbH | |

| Position | Expert for design of SBR plants, biological sewage purification | |

| Description | Design of all constructions and equipment of the plant operating according to the SBR principle. The capacity of the plant amounts to 29,200 p.e.60. (upgrading in 3 construction phases) | |

| · Detail engineering of all constructions and equipment of the plant according to European standards | ||

| · Hydraulics | ||

| · Preparation of the offer of the company for the tender | ||

| Year: | 1998 | |

| Location: | Manila (Philippines); Vienna (Austria) | |

| Employer: | Puraqua Umweltanlagen GmbH | |

| Position | Expert for design of SBR plants, biological sewage purification | |

| Description | Design of all constructions and equipment of the plant operating according to the SBR principle. The capacity of the plant amounts to 56,000 p.e. (upgrading in 3 construction phases | |

| · Detail engineering of all constructions and equipment of the WWTP according to European standards | ||

| · Hydraulics | ||

| · Preparation of the offer of the company for the tender | ||

Straubing trickling filter

Ardiya pump station

Bizerte aeration basin

Bizerte sand trap

Drnis ox basin

Drnis ox basin

Durres aeration basin

Durres clarifier

Durres erration field

Durres overview

Durres scraper

Ghardimaou clarifier

Hainburg aeration field test

Hainburg aeration fields

Hainburge aeration field test

Ivano clarifier effluent

Ivano clarifier empty

Ivano clarifier effluent

Ivano concreting clarifier

Ivano ox basin construction

Kavaje sprinkler 1

Kavaje sprinkler 2

Kavaje trickling filter

Mornag clarifier effluent

Mornag oxidation basin 1

Mornag oxidation basin 2

Mornag pretreatment

Siliana clarifier

Siliana sand trap scraper

Siliana sand trap

Siliana sludge drying bed

Siliana Sludge drying beds

Skenderaj pretreatment station

Skenderaj trickle filter

Sousse surface aerator

Sousse trickling filters

Straubing clarifier

Straubing conveyor

Straubing intermediate clarifier

Straubing internal pumping

Straubing sprinckler detailed

Straubing sprinkler

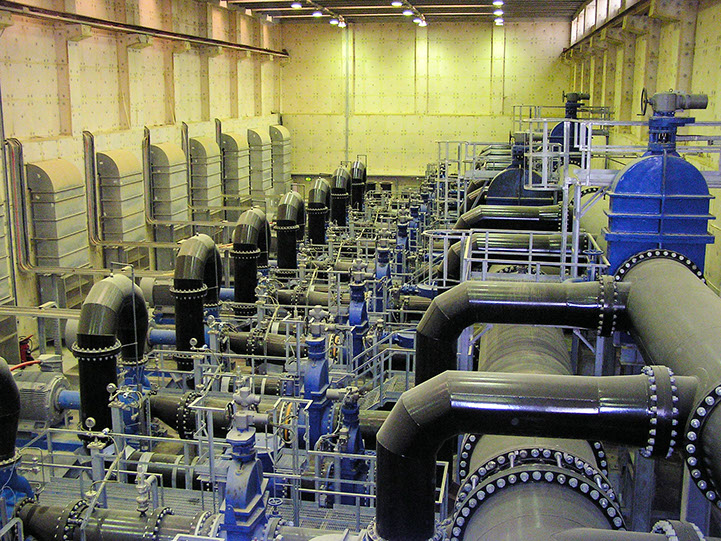

Sulaibiya ox Basin

Sulaibiya ox Basin

Sulaibiya scraper

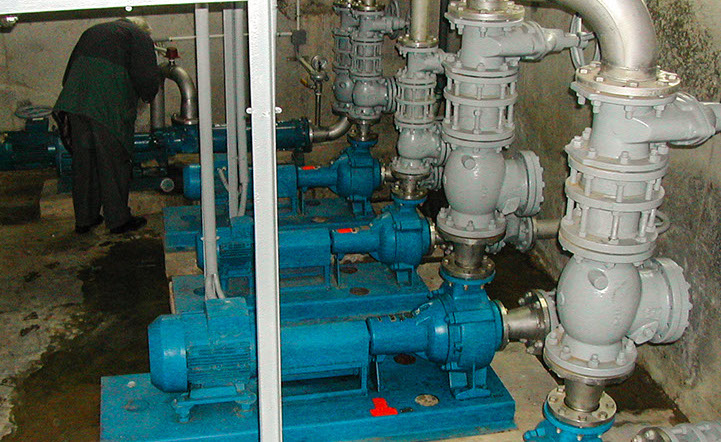

Testor pump station

Testour sans trap

Vienna WWTP